Measured by our precision. Valued for our service.

Lumetrics is a leading manufacturer of precision non-contact thickness measurement and optical inspection systems for a variety of critical applications in medical devices, glass, food packaging, ophthalmic, automotive, and film industries. We offer test and measurement services for a wide array of products and materials as well.

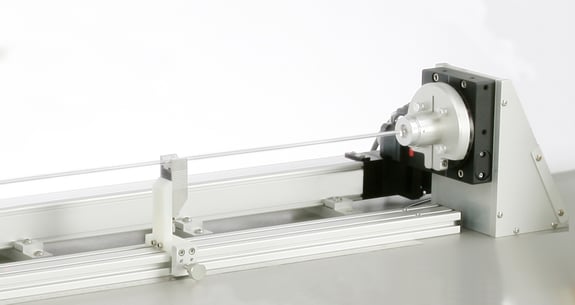

Our breakthrough precision thickness measurement technology is fast, accurate, flexible, and scalable to most QA laboratories, R&D centers, or production lines. Lumetrics provides off-the-shelf products as well as custom metrology solutions and discovery services to meet even the most complex measurement and testing requirements.

Partnering with Lumetrics means personalized service, direct collaboration with our engineers, and a working relationship that is developed around your needs and your success.

Precision Measurement Solutions

From medical devices to food packaging, automotive glass, and contact lenses, for accurate, precise data helps improve quality and increase yields.

Read MoreCombining Shack-Hartmann sensors, beam profilers, and software form systems that analyze optics-related products and materials.

Read MoreWe know that many applications have unique requirements only a customized system will fit. Our engineers work with you to develop a metrology system that integrates with your specific environment.

Read MoreWHAT WE MEASURE

From multi-layer film thickness measurement and quality assurance inspection to high-precision, real-time dimensional measurement of medical devices, Lumetrics builds metrology solutions that enable fast, accurate, and non-destructive results. Adopting a Lumetrics measurement system significantly reduces waste, creates efficient manufacturing processes, produces better end products, and increases profit margin.